Back in November 2021, a group of intrepid graduates accepted the call from the UK Students for the Exploration and Development of Space (UKSEDS) and gathered to work on a project that would take them to MARS! (Via Stevenage and Harwell)

The first critical task at hand was to come up with a name. After much deliberation, it was settled on "They See Me Roving" or TSMR for short. Then after that most difficult of choices, we had to design a Rover capable traversing the terrain of Mars and safely retrieve a set of samples. Working against strict limits on weight, size, and numerous other requirements, this was no easy feat. The graduates organised themselves into groups dealing with different Work Packages including: Control & Electronics, Power, Autonomy & Software, Propulsion & Chassis, and Manipulator. Leading the effort was Jan Sprengel as Project Manager, who kept all the groups in check and kept a keen eye on what needed to be done and when it needed to be done by, putting our Systems Engineering training to good use.

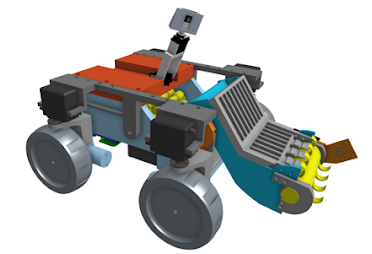

By December, the graduates had a Preliminary Design to

submit to UKSEDS for review. The result of much research and design work, it

was a bit rough but showed we had a solid concept of the rover.

|

| CAD model of the TSMR Rover |

The judges at UKSEDS then greenlit the team to continue to a

final design. A lot of features were refined as the design faced the realities

of component procurement and manufacture. Faced with a limited budget, it was

decided to construct the rover from 3D printed parts on-site. As parts were prototyped

and improved, the rover ended up being manufactured in stages, which resulted

in the “distinctive” colour scheme of the final design.

|

| The actual rover, with trademark multicolour aesthetic, settling well into its natural environment of "Mars" |

Held together by many M5 screws and the hopes and dreams of the graduate team, the rover made its way to Stevenage on the 6th of August for performance testing at the Airbus Mars Yard in Stevenage. There were 9 teams competing to score the highest with their rover, each with their own approaches, including one made simply from cardboard. However, upon initial set-up, it was found that our rover was facing technical issues. After a day of troubleshooting the electrical and control system, we tried hardwiring a connection over ethernet cable, yet the rover just sat stoically at the start line, despite it having worked brilliantly the previous day. Sadly, another example of the well-known Murphy's Law at play.

We then sat on the observation deck and watched as

other rovers similarly faced a gauntlet of technical issues including getting

themselves stuck in sand, being unable to climb the rocks, and difficulties with manipulating the sample collection tools. Eventually, even the best performing

rover only picked up a single sample before returning. We nevertheless cheered all their brave efforts and took away many lessons learnt on rover design.

|

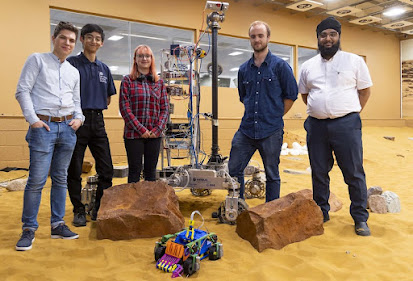

| Some of the elite TSMR rover team of graduate engineers with their rover (front), and the slightly bigger Airbus rover (back) |

The next day was spent at RAL Space over at the Harwell

Campus.

The big event of the day was a vibration test where the rovers were affixed to

a test rig and shaken rigorously. A slow-motion video of the test shows our rove

|

| The rover is bolted down to the test rig, to be given the much-feared "vibe test" |

Overall, the team was very proud to have made a rover on such a short timescale, and

even though it didn’t manage to move on the Mars Yard, we got a lot out of the

process of planning, designing, and building the rover from start to finish in

only a few months. Even so, the design still was commended by the judges. They

particularly liked the custom PCB, the inventive “sand-sweeper” sample

collection tool, and the awesome digital twin model of the rover (please see the video

below), so they awarded the team with the ORT Innovation Prize!

|

| The ORT Innovation Prize - a 1:1 scale 3D-printed model of a Mars sample tube |

What next for our little rover? The team are hoping to

repair the damage, get it better than before, and use it to showcase our

brilliant engineering efforts on Outreach events. So, the rover will rise

again!